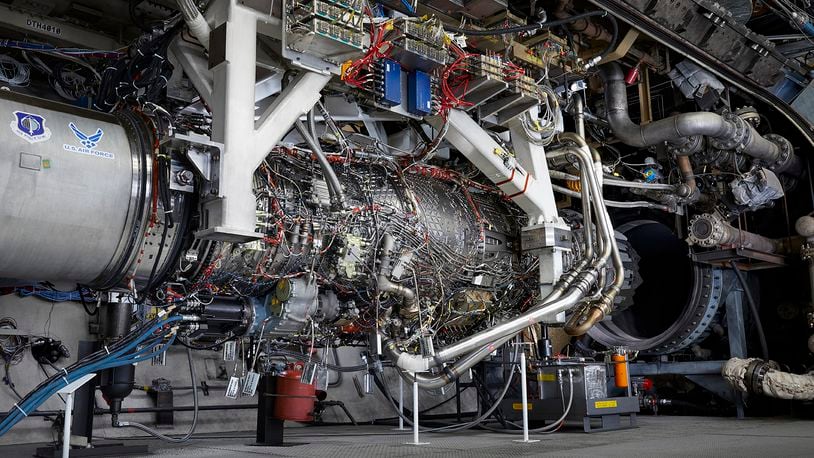

Full-scale prototype engine testing in the AETP program is the capstone of years of work, GE said. The Air Force Life Cycle Management Center Propulsion Directorate, based at Wright-Patterson Air Force Base, oversees the program.

In plain terms, the goal with the adaptive engine is to give pilots not only the ability to cover long distances, but to have the thrust power needed for combat even after long jaunts.

Lighter, stronger materials come together to enable engines to be more fuel-efficient while offering power.

“It means more range and more combat effectiveness,” David Tweedie, GE’s general manager of advanced combat engines, says in a new video from GE.

GE’s first XA100 engine tests began in December 2020, marking what GE says is world’s first ever run of a flight-weight three-stream adaptive cycle engine.

Tests validated the engine’s ability to deliver “transformational propulsion capability to current and future fighter aircraft. Engine prototypes assembled as part of AETP are designed to fit and integrate directly into the F-35,” GE said.

The result is an increase in thrust of 10%, improved fuel efficiency by 25%, providing “significantly more aircraft heat dissipation capacity, all within the same physical envelope as current propulsion systems,” GE said.

“The U.S. Air Force and Congress have invested more than $4 billion in adaptive cycle engine development over the past 14 years to mature its associated technologies,” Tweedie said in a release from GE. “We’re confident this phase of the program will significantly reduce risk and prepare GE for a low-risk engineering and manufacturing development program, consistent with Air Force objectives.”

GE Aviation makes commercial and military jet engines and parts, and before the COVID-19 pandemic, it had more than 9,000 employees in Southwest Ohio, including its plant in Evendale.

The GE Aviation EPISCenter on the University of Dayton campus researches electrical power in aviation uses. In recent years, there were about 335 GE Aviation employees in Vandalia and about 1,600 total employees at three Dayton-area sites — including Unison Industries Dayton in Beavercreek and TDI-GE Aviation, also in Vandalia.

About the Author