“With this machine we are able to build shapes that you can’t build any other way,” said Joy Gockel, assistant professor of mechanical and materials engineering. “You are able to take the theory you learned in your fluid dynamics class and you can actually implement the theory into a design. You can create some really complex internal structures.”

Small micron-level particles of metal powder are spread across the bed of the printer. Then a high-powered laser beam melts the powder and forms it into pre-designed metal shapes.

3D printers that use plastics can make parts, but the plastic materials are usually only good for prototypes because the material is not as strong as metal.

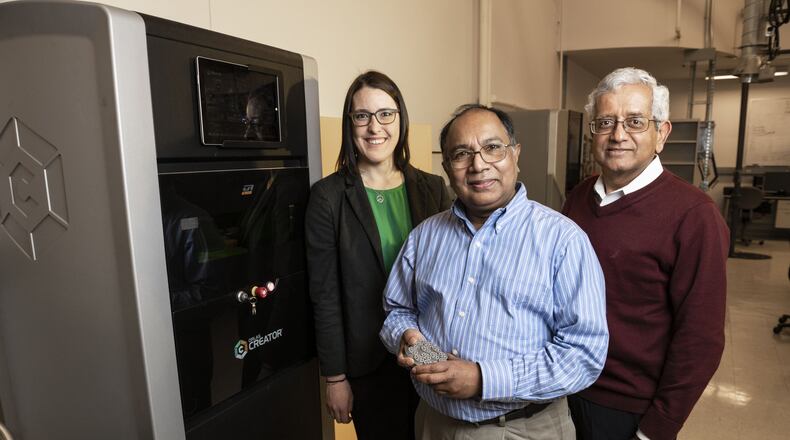

The metal printer is used by graduate students to conduct research and in undergraduate additive manufacturing classes, with students exploring the power of the laser and how it influences materials.

They have investigated the capabilities of the printer, producing small metal objects. For example, they have made simple geometries such as cubes and a staircase-like object as well as sample parts such as gears and turbine blades. A senior design team plans to use the printer to build a customized nosecone for a turbine jet engine designed to aim its thrust in different directions.

“There are machines like this that are making parts that are in airplanes now, in engines,” said Gockel.

She said Wright State is the first organization in the area to have the use of this metal printer. She said it is making students knowledgeable about the technology and preparing them for engineering jobs that involve 3D printing.

“They’ve seen the equipment. They know the capabilities,” she said. “If they come across an application that would be good, they can take advantage of the really complex design.”

Gockel said the Dayton region is a hub for additive manufacturing, with aerospace companies and medical parts supplies all using the technology.

“We have students who are going out and graduating and getting jobs specifically working with this,” she said.

Ahsan Mian, associate professor of mechanical and materials engineering, said metal printers could be used to make better fitting hip replacement parts. Mian said the Air Force Research Laboratory at Wright-Patterson Air Force Base invests heavily in designing and developing metal parts with internal functions and employs many Wright State graduates.

“AFRL is a big recruiter,” he said.

About the Author