State-of-the-art metal 3D printers promise to revolutionize manufacturing but have not reached optimal operational reliability. One challenge is to control complex, interdependent laser-powder-melt pool dynamics to avoid the formation of defects.

Dr. Eddie Schwalbach, research materials engineer at the Air Force Research Laboratory’s Materials and Manufacturing Directorate, is responsible for performing in-house research and monitoring external projects dealing with metallic additive manufacturing technologies.

Schwalbach is part of a larger team at AFRL that includes Drs. Megna Shah, Michael Chapman and Kevin Chaput (Northrop Grumman) that utilized advanced 3D metallographic techniques known as serial sectioning to complement advanced process-modeling work performed at Lawrence Livermore National Laboratory, California.

“The collaboration is an excellent example of how cutting-edge materials characterization tools and advanced process modeling can be combined to investigate behaviors in the AM process that can lead to detrimental flaws,” said Schwalbach.

AM is similar to laser welding in that it is known to produce material with defects that can degrade the strength/mechanical properties, thus limiting the use of the technology for demanding aerospace applications. Such defects can be a result of seemingly trivial changes in processing details.

The nature of defects produced by AM processes can offer a link to the mechanism responsible for forming them, which is, in turn, necessary to either better control or improve existing design processes.

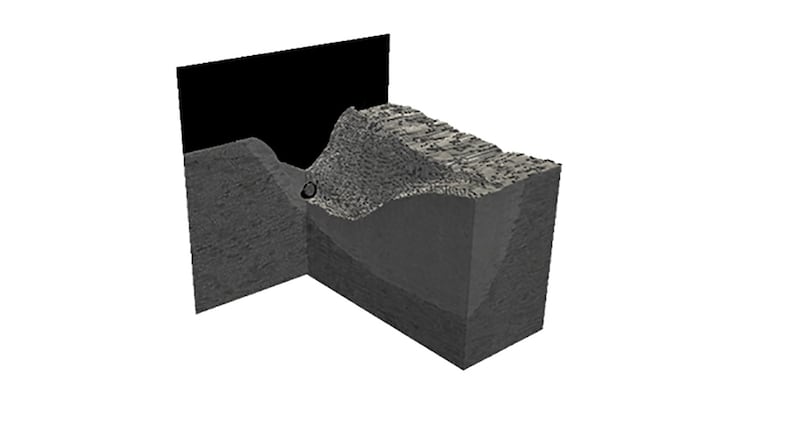

Specific concerns during printing include the ejection of “spatter,” liquid droplets or entrained powder particles that undergo expulsion from the melt pool and appear as the sparks or smoke in videos of metal AM printing, and the formation of a depression on the deposited surface that can lead to entrapped voids The modeling tools were used to test processing strategies to eliminate these performance limiting behaviors, and ultimately present a roadmap for reducing spatter and decreasing voids in metal AM parts.

The work sheds light on mechanisms that form defects and offers a solution for avoidance.

The modeling work and process designed/executed by the Lawrence Livermore National Laboratory authors is cutting edge. AFRL provided highly detailed characterization to confirm the nature of the end-of-track depressions and subsequent void formation.

High-fidelity multiphysics simulations coupled with in situ diagnostics will be indispensable in introducing stability criteria to advance manufacturing and help usher in the industry revolution.

For further information on controlling interdependent meso-nanosecond dynamics and defect generation in metal 3D printing, see “Science,” Vol 368, Issue 6491, May 8, 2020.

About the Author