PMC materials consist of strong fibers embedded in a resilient plastic that hold them in place. The Air Force uses PMCs on many parts of the aircraft. They are much lighter and cheaper than other materials.

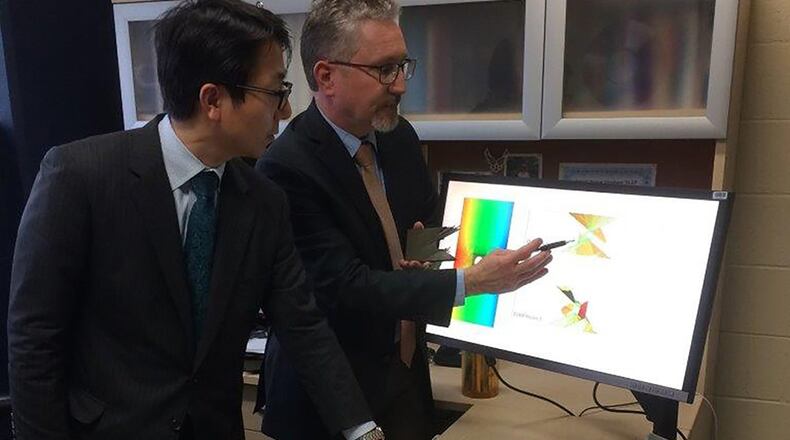

Umezawa’s primary work focuses on the modeling of damage evolution in PMC materials using an AFRL-developed research software package. This tool, known as BSAM, is a result of many years of research and development led by Dr. David Mollenhauer of AFRL’s Composite Performance Research Team.

The stress analysis software simulates damage processes in composite materials. Specifically, damage in PMCs is characterized by complex networks of cracking in the polymer matrix, delamination between layers and fiber fractures.

Umezawa is training on the software and then developing a variety of PMC damage simulations. His primary simulation campaign will focus on simulations of laminated PMCs that have a long, thin saw-cut, mimicking a crack, and observe how damage grows from these “cracks” within the BSAM simulation environment.

As with AFRL, the JMoD has come to the realization that commercial PMC damage codes are lacking in capability. BSAM has limited, but growing exposure in the research and design community. Training Umezawa in the use of this advanced code is a continuing step in spreading the word about this new useful tool.

“I’m happy to work as an ESEP engineer in AFRL and very excited to join the project on BSAM,” said Umezawa.

His efforts aid an ongoing experimental effort that examines damage in PMCs. Additionally, Umezawa brings insight to the U.S. Air Force on composite research and development at the JMOD, especially in relation to the new Japanese fighter program.

“I’m elated to work with Dr. Umezawa to further enhance the strong relationship between the U.S. Air Force and the JMoD’s Air Systems Research Center,” said Mollenhauer.

Hands-on use of AFRL products by colleagues benefits the U.S. Air Force by providing feedback on usability, capability and needs. Umezawa will aid in the evaluation of the simulations against experimental results gathered at AFRL, resulting in a better understanding of the BSAM code’s effectiveness.

About the Author