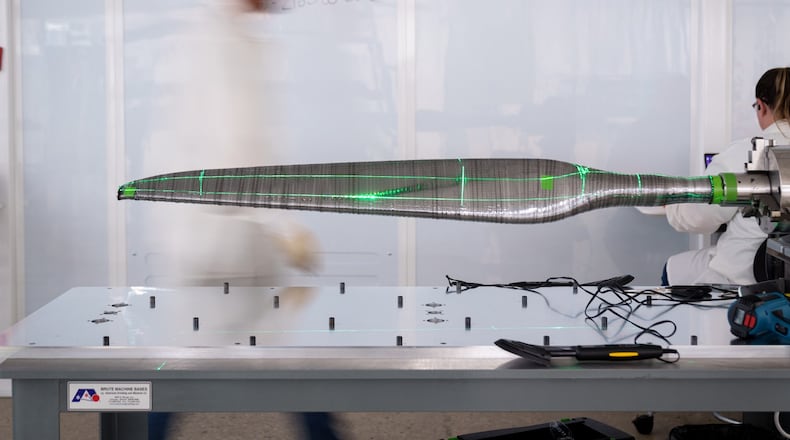

“Dayton gives us the resources, talent, and speed to scale one of the most technically demanding parts of our aircraft,” Eric Allison, Joby chief product officer, said in a release. “Joby’s propeller blades are a key part of what makes our aircraft special — central to its low acoustic profile and the result of a decade of complex engineering.”

Joby makes electric aircraft that liftoff and land like helicopters while cruising like airplanes, all quietly. The company hopes to command a market of quickly ferrying airline passengers across big cities while also serving the military.

The propellers are designed for quiet flight but “built with extreme precision,” Joby said. With five blades per propeller and 30 per aircraft, production could reach up to 15,000 blades a year as part of Joby’s plan to scale up manufacturing in Ohio.

Conforming with Federal Aviation Administration inspection and certification standards for the blades is expected to happen next month, with installation on flight test aircraft targeted for next year, the company said.

“Over time, Joby’s Dayton footprint is expected to be able to support production of up to 500 aircraft a year, making this facility a strategic site for the mass production of its aircraft components,” the company said in its announcement.

Joby chose Dayton for its heritage of aerospace and advanced manufacturing, a highly skilled local workforce, and close proximity to critical suppliers, including Toyota, a company which has been a key investor in Joby for years.

With nearly every component needed for blade production available within a 30-minute radius of the site, the Dayton region provides a “strong foundation for efficient, high-quality manufacturing at scale,” Joby said.

Joby has a smaller production line near its California headquarters. The Dayton site, a former U.S. Postal Service sorting facility off Concorde Drive near the airport, is expected to become the company’s long-term hub for blade production.

Joby said it intends to host an event at the Dayton facility Nov. 10 so leaders can talk more about their Dayton plans.

“Together with our partners at the Dayton Development Coalition and the DeWine-Tressel administration, we are proud to welcome Joby Aviation’s decision to establish Dayton as its blade production hub, building on its major aircraft manufacturing commitment announced in 2023,” JobsOhio President and Chief Executive J.P. Nauseef said in a statement. “This new investment underscores Joby’s confidence in Ohio’s aviation legacy, innovative talent, and advanced manufacturing strength, and reinforces Ohio’s role in shaping the future of flight.”

The Dayton area has a history of making aircraft propeller blades and other aviation-oriented components. McCauley Propeller Systems started making propeller blades in the 1930s in Dayton. Hartzell Propeller, in Piqua, was founded in 1917 as the Hartzell Walnut Propeller Company.

“Joby’s official start of propeller production at their Dayton facility brings Ohio’s legacy of aviation innovation to Joby’s aircraft,” said Jeff Hoagland, president and CEO of the Dayton Development Coalition. “The technical, precision production work relies on the talent of the Dayton region’s skilled manufacturing workforce. This work builds the foundation of Joby’s operations here in Ohio, and we will be with them every step of the way.”

About the Author